Roofing materials and technologies are continually becoming more advanced.

The purpose of this guide is to help you understand the different types of roofing materials that are available for both residential and commercial roof systems.

This guide will cover topics such as what the material is made of, the price per ‘square’ or per 100 square feet, the durability level in weather conditions, and the expected lifespan.

The roofing materials that I cover are listed in alphabetical order for your convenience.

Click on the material to jump to that section of this article.

Click Here To View Quick Reference Tables for Price Comparison of Materials

Asphalt Shingles

Asphalt shingles are probably one of the most common types of roofing materials used today. They come in a variety of styles and colors that can complement many different styles of homes.

Materials Used:

Asphalt Shingles contain a membrane that is either made out of organic materials such as wood, cardboard, and paper. Or they have a fiberglass membrane.

The fiberglass membrane is better because it gives the shingles a class A fire rating as opposed to the class B that comes from the organic membrane.

The organic membrane is not used as much today as the fiberglass membranes.

Each type of membrane is covered in several layers of asphalt, the top surface is then covered in a ceramic coating. The ceramic granules are made out of solid volcanic lava, basalt, or granite that has been ground down.

Some manufacturers will even mix other ingredients like copper with the granules to prevent algae from growing on the shingles and creating black streaks.

Style Options:

Asphalt shingles come in a variety of styles. The more unique the style is the more likely it will cost more per square.

Ultimately there are 4 main types of styles which are:

- 3-Tab Shingles

- Designer Shingles

- Architectural

- Special Architectural

3-Tab Shingles:

3-Tab Shingles are usually the most affordable option. Just as with the other styles of shingles, 3-Tab Shingles come in a variety of colors that can meet any house style.

Price: On average, the 3-tab shingles range about $75.75 – $89.40 per square (Note: 100 square feet = 1 square and 3 bundles to 1 square).

Durability: From my experience, 3-Tab Shingles are not very durable. They are the most affordable type of shingle but as the expression goes, “You get what you pay for.”

3-Tab Shingles are usually the first to go in a storm. They have the lowest wind resistance out of all the other styles which are about 60 MPH or 97 KMH.

Additionally, from my experience of doing hail damage inspections, 3-Tab shingles are very susceptible to hail damage.

Expected Lifespan: 3-Tab shingles don’t last as long as the other types of asphalt-shingles. Their expected lifespan is about 10-20 years. Even less if you live in a storm-prone area.

Designer Shingles:

Designer Shingles are made to look different than the other types of shingles. Often designer shingles are cut to mimic the shapes of other roofing types like wood-shake, or slate tiles. But they come in a large variety of different styles.

They look nice on homes and they come in a variety of colors to match any style of home.

Price: It really depends on what style of shingle you are looking at. A good range could be about $100-$220 per square. You can always call your local roofing supplier and get a quote from them.

Durability: Designer shingles are more durable than 3-tab shingles. However, they tend to have less wind resistance than architectural shingles.

The wind resistance of Designer Shingles is about 110 MPH or 117 KMH.

Designer shingles hold up better during hail storms as opposed to 3-tab shingles. However, the older it is, the more likely it will get damaged in a hail storm.

Expected Lifespan: The lifespan of designer shingles is a bit longer than architectural shingles and a lot longer than 3-tab shingles. On average the expected lifespan of Designer Shingles is about 30 years.

Architectural:

Architectural Shingles is one of my personal favorites because I really like the look of them. From what I have seen, this style of shingle is one of the more popular styles.

Price: Architectural shingles cost about $95.70 – $99.00 per square.

Durability: Architectural Shingles are definitely more durable than 3-tab shingles. But they are about the same level of durability as the Designer Shingles when it comes to hail damage.

Architectural Shingles have a higher wind resistance than the 3-Tab Shingles and the Designer Shingles. It averages about 130 MPH or 209 KMH which is great if you live in a windy area.

Expected Lifespan: Architectural Shingles have a higher life span than the 3-Tab shingles but slightly less lifespan than the Designer Shingles.

The average lifespan of the Architectural Shingles is about 22 – 25 years.

Special Architectural:

Special Architectural Shingles are a type of Architectural Shingle but with unique qualities. I can’t name all the special architectural shingles available today. But I can focus on two main types of Special Architectural shingles which are Storm Resistant and Solar Reflective.

Storm Resistant Shingles are made for storm-prone areas. They are made with extra coatings of asphalt and granules making it a thicker shingle.

Solar Reflective Shingles are made out of more reflective materials in order to reflect the sun’s UV rays and keep your house cooler in the summer.

Price: The price varies depending on what unique qualities they have, but a good range would be $140 – $220 per square.

However, it’s important to note that the Solar Reflective will help you save a little on your energy bill during the warm seasons because you won’t need to use your air conditioning as much.

Durability: The Solar Reflective Shingles are about the same level of durability as the normal Architectural shingles.

The Storm Resistant Shingles are the most durable out of all the Asphalt Shingles. They are made to have a UL 2218 Class 4 impact resistance, which is great for resisting hail damages.

The wind resistance of both the Solar Reflective and the Storm Resistant are the same as the Architectural Shingles which is about 130 MPH or 209 KMH.

Expected Lifespan: The lifespan of Special Architectural ranges anywhere from 30 years to 50 years depending on the style you get.

Click Here to read 13 Pros & Cons of Asphalt Shingles

Back to Top

Built-Up Roof (BUR)

Built-Up Roofs also are known as “tar and gravel” are not as common today as they used to be, but they can still be found on flat or low pitch roofs. They are primarily used for commercial buildings but can also be found on residential homes with a low pitch or flat roof.

Materials Used:

The Built-Up Roof consists of multiple layers of various fabrics alternating with a layer of bitumen (asphalt). The last layer is topped with rocks or gravel.

Essentially, this is like turning the entire roof into one giant shingle. Just as an asphalt shingle is a tar-covered membrane coated in granules. The BUR also consists of membrane fabrics, asphalt, and rocks.

The gravel is very effective because it helps keep the base of the roof cool while also holding heat to help evaporate water off the top.

The gravel also helps with traction for all seasons of the year. Another benefit of the gravel is that it helps keep the roof drains free from clogging with leaves and other debris.

Style Options:

There are several types of Built-Up Roof systems or BUR systems but I am just going to focus on two main styles in this section. Some of the other types that evolved from the main BUR will be addressed later under Modified Bitumen roof systems.

The two main types of BUR is the Tar & Gravel and the Ballast Roof system.

The main difference between the two types is with the last layer of gravel. With the Tar & Gravel system, the gravel is sealed down onto the roof by the asphalt tar. This layer of gravel is thinner compared to the Ballast Roof system.

Meanwhile, the gravel on the Ballast Roof system is loose and is applied as a thick layer several inches to a foot deep.

The size of the two types of gravel is different as well. The gravel of the Tar & Gravel is about 0.25″ – 0.5″ inches (0.64 cm -1.27 cm) in diameter. Where the Ballast stones are about 1.5″ – 2.5″ inches (3.8 cm – 6.4 cm) in diameter.

Because of the size difference and the layer difference, the Ballast roof system is much heavier than the Tar & Gravel system.

The Ballast roof system weights about 10 to 25 lbs per square foot. This roof system needs a strong roof structure to support the weight.

Price: The price for the materials of a Built-Up roof system can cost about $165 to $250 per square.

Durability / Lifespan:

Durability: Built-Up roof systems are very durable. The gravel on the surfaces provides a lot of protection from UV rays.

Because of the gravel, it is also very resilient against impact damage from hail storms.

However, during a strong wind storm, the Ballast roof can lose stones because they are not sealed down, like the Tar & Gravel.

Lifespan: Built-Up Roof (Bur) typically will last at least 5 years for each layer of ply. If properly installed, a 4-ply roof system can be expected to last 20 years or more. It not uncommon to find roofs that will last 40 years.

Click Here to Read About the Pros & Cons of Built-Up Roofs

Back to Top

Clay Tiles

Clay tile roofs have been around since ancient times. They are often chosen for their unique style and durability. The downside to this type of roof is its weight. Clay tiles are considered a heavyweight roof system because they weigh much more than shingles or metal.

Materials Used:

Clay Tiles are made out of, well. . . clay. The popular terracotta clay is often used which contains iron that gives the clay that distinct red color.

Often times special glazes that may contain chemical compounds like silica, manganese, fluxes and aluminum oxide are used to increase durability and alter the color.

The cost of materials can range between $50 – 100 per square, so a bit more pricey than other tile options.

Durability / Lifespan:

Durability: One of the major benefits of clay tile roof systems is its durability. Clay is probably one of the most durable materials because it doesn’t degrade from exposure to the elements.

Take for example ancient clay pots and bowls that have been discovered by archeologists. Those have lasted for thousands of years along with the clay roofs found in countries like Italy and Greece.

The clay tiles are considered a Class A fire rating and can withstand 2-inch sized hail which is a Class 4 impact rating.

If properly installed they can even withstand winds up to 200 mph. They provide excellent protection against UV rays, which is why they are common in hot climates.

Lifespan: Because of its high level of durability, this type of roof system can be expected to last anywhere from 50 years to 100 years.

If you have a really high-quality tile then it can be expected to last over 100 years.

It’s important to keep in mind that the underlayment material beneath the tiles will not last nearly as long. The underlayment may need to be replaced after about 20-30 years.

Style Options:

There are many style options available but I am just going to talk about some of the common styles.

Classic S-Shape:

There are a couple of variations of the S-shape style. They can come in one-piece or two-piece styles with different glazes. The benefit of the S-shape is that it combines the top cap and the bottom pan pieces together.

This makes for lower material and installation costs. It usually takes about 75 – 90 pieces per square to install. That can weight about 788 lbs per square. The pieces per square and weight will vary depending on the manufacturer and the specific type of tile used.

Price: About $200 to $400 per square to install.

Barrel Shape:

The Barrel Shaped style generalizes a variety of tiles with the basic barrel shape. It’s been rumored to have originally been formed by sculpting the clay around a human’s thigh. The distinct barrel shape tile is common for Spanish and Mediterranean roof styles.

There are several variations of this style. The basic straight barrel doesn’t have any modifications.

Other styles have minor revisions like a tapered end or a flat base and curved cap like the Italian model. The different variations play a role in how the tile looks especially as the sun hits it during different times of the day.

The pieces per square can fall anywhere from 130 to 180 pieces. While the weight can range between 910 lbs to 1050 lbs per square.

With that said, if you have a home that is 30 squares that would be a 31,500 lb roof. This is why clay tile roofs are considered a heavyweight roof system. If you want this style of roof you will need to make sure your home is built to support that kind of weight.

Price: About $300 to $650 per square to install.

Flat Tile:

Flat tile roofs are can give a more modern looking style roof. However, you can get them with different textures to mimic other styles of roofs like slate, shake, or a more weathered look.

What is the difference between tile and slate? Tiles are manufactured out of terracotta clay and can be texturized to fit different styles. While slate is a natural fined grained metaphoric rock that is cut and shaped to fit.

But I will talk more about slate later on down below. The weight per square is about 800 lbs to 1780 lbs per square. The pieces per square can range from 108 pieces to 879 pieces per square.

Price: About $229 – $249 per square to install.

Asian Style:

China was actually one of the countries that have been using clay tile roofs since ancient times. Over time it spread to other Asian countries like Japan.

This type of roof is a traditional design that is usually found in the ancient black color. This was commonly used for temples and tea houses. This style features various decorative ornaments that give it that traditional look we often see.

If you don’t use any of the fancy ornaments then this design can be used for western or more of a contemporary style.

This type of tile can weight about 864 lbs per square and can take about 144 pieces to cover a square.

Specialty Tiles:

Specialty tiles are kind of like the “other” category. It would take too long to talk about every single type of style of tile that is possible.

Many manufacturers will offer customized tile shingles. This is the perfect option for those who are looking to do building restorations.

You can send the company a sample piece of the clay tile and they can duplicate it for you.

Specialty tiles can be used for unique structures like domes, and turrets. This would also be a great option for commercial buildings looking for a very unique look.

As you probably know, the prices and the pieces per square will vary greatly depending on the project.

Click Here to read 17 Pros & Cons of Clay Tile Roofs

Back to Top

Concrete Tiles

Concrete tiles are another great durable heavy-weight roof option. They are very similar to clay tiles in many ways but maintain some key differences.

Materials Used:

Concrete tiles are made out of a mixture of sand, cement, and water. Each tile is formed by molding it under high pressure and heat.

Color is added to the tiles in one of two ways. The first is by adding a pigment to the concrete mixture.

This process allows the color to mix throughout the entire tile. It is most commonly done for subtle colors.

The second way color may be added to the tiles is by covering the surface of the tile with a slurry mix of cement infused pigment. This is most commonly done for bright and high contrast colors.

Style Options:

Just as with clay tiles, concrete tiles come in a variety of styles. They can be made to mimic the textures of wood shake, clay, slate, and stone. Concrete tiles offer a more affordable option to some of the more expensive styles like slate.

The tiles can also come in a variety of profiles starting with low profile or flat, then medium, and lastly high profiles like that of a high profile barrel.

Concrete tiles are another heavyweight roof system. That means if you are looking to replace your asphalt shingle roof with concrete tiles, you will likely need to add more support to your roof.

The standard weight for concrete tiles ranges from about 900 lbs to 1200 lbs per square.

Due to the weight of the tiles, some manufacturers and distributors offer lightweight options without the loss of durability.

These lightweight tiles weight about 500 lbs to 720 lbs per square

Durability / Lifespan:

Durability: Concrete tiles are very durable. They share many strengths with clay tiles. However, they do have some disadvantages.

Concrete tiles are heavy enough to uphold snow loads and to not lift up in the wind. They are rated for wind speeds up to 180 mph. The tiles are naturally a Class A fire rating and a Class 4 impact rating, which means it can resist impacts from a 2-inch size hail.

The tiles are also great at providing UV protection, and insulation because it’s a low heat transfer material.

Lifespan: The lifespan of concrete tiles ranges from about 30 to 50 years. This is still a long time when compared to asphalt shingles, but not nearly as long as some of the ancient clay tile roof systems.

One disadvantage to concrete roofs that is not a problem with clay roofs is that the color will fade with time. Concrete is more porous than clay and so it absorbs a little bit more water.

When you mix water with carbon dioxide then combine it with the lime in concrete it creates a reaction called efflorescence.

Efflorescence causes a white chalky substance to appear on the surface of the concrete. The white substance is caused by the soluble salts rising to the surface of the concrete.

This looks stained at first but can be cleaned off. This can also happen with the slurry-coat of bright color pigments that color the surface of the tiles.

The slurry colored pigment used to “paint” the surface of the concrete tiles will eventually wear down to the base material and expose the natural colors of the concrete.

This is something that doesn’t happen with clay tiles because they are usually colored throughout the whole tile.

Now you might be thinking, “But wait didn’t you say that concrete tiles are colored throughout the whole concrete using a pigment?”

While that is true that that method is used, the coloration is still affected by weathering. Unlike the clay tiles, after a while, the color on the surface of the concrete tiles will begin to fade.

Nonetheless, this type of fading is surface-level only because the base of the material was colored throughout. Due to this fact, the base material will still maintain its original color pigment.

So if color is a key component for whether you want clay tile or concrete tiles it would be better to go with clay tiles if you can afford it. Another key difference between the two types of roof systems is the price.

Price: Generally speaking, the price of concrete tiles are more affordable than the price of clay tiles. Concrete tiles cost about $40 to $90 per square. That doesn’t include installation costs.

Click Here to read 16 Pros & Cons of Concrete Tile Roofs

Back to Top

EPDM Rubber

EPDM Rubber is a flat roof system that is most commonly used for commercial roofs. It was developed around 1962 but first, became popular during the ’70s. Making it newer than BUR systems but slightly older than other flat roof systems.

Materials Used:

EPDM stands for Ethylene Propylene Diene Terpolymer. The Terpolymer is composed of three different Monomers, hence the “M” in EPDM.

EPDM is a rubber-based material that has many different uses. You know what EPDM looks like if you have ever seen the black rubber that seals your car doors, windows, and trunk.

Its elasticity and water resistance make it a goof flat roof system.

Manufacturers claim that EPDM has the lowest carbon footprint when compared to other single-ply roof systems. However, in my opinion, EPDM rubber doesn’t strike me as the most “green roof” system out there.

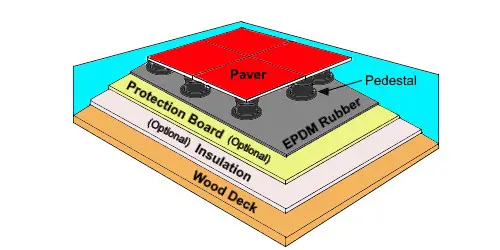

Style Options:

When it comes to EPDM rubber and most flat roofs, in general, there aren’t a lot of style options.

EPDM rubber can come in two colors, white, or more commonly black.

The size of the sheets of material can come in a width anywhere from 7.5 ft to 50 ft. The thickness of the material ranges from 30 – 90 mils. Which is equivalent to 0.030 – 0.090 inches. To give you an idea of what that looks like, an average penny is about 0.0598 inches thick.

There are three ways in which it can be attached to the roof.

- Fully Adhered – using a special liquid adhesive or tape.

- Mechanically attached – using a designated type of screw and plate.

- Ballasted – secured by the weight of stones (learn more by reading

Style Options for BUR system)

EPDM can be considered a lightweight roof system (excluding the ballasted version) due to the fact that the EPDM material weighs less than 2 lbs per square.

Durability / Lifespan:

Durability: The EPDM roof system is a durable roof system because it is resistant to UV radiation and hail damage.

Further impact resistance can be added by strengthening the roof with reinforced membranes or by adding pavers similar to the IRMA roof system. This will prevent damages from Bird pecking and Clam dropping.

With flat roof systems, you may see an uplift rating ratings such as 1-60, 1-90. This is the rating measured in pounds of how much pressure one square foot of the material can take before failing. So a 1-60 rating means that one square foot of the material can withstand about 60 pounds per square foot of pressure before failure.

There is more to the rating system than what I am explaining but for simplicity, I am just giving you the basics.

EPDM rubber can be made to meet several different uplift ratings include 1-60, 1-90, and 1-120.

When compared to other flat roof materials like PVC, and TPO, EPDM is more flexible because of its elastic properties. This means it will stretch and contract better in areas that have fluctuating temperature changes.

Each of these factors plays a role in the overall lifespan of the roof.

Lifespan: The life expectancy for an EPDM roof system can range from 20 years to about 30 years.

Another thing to consider that may cause problems and reduce the lifespan of this roof is ponding. This can happen with almost any type of flat roof. Ponding is when the roof does not have proper water drainage.

Additionally, sometimes the seams of this roof don’t properly hold, so as the rubber based material expands and contracts the seams pull apart causing a leak in the roof system.

These are just some of the things you might see as the roof naturally weathers down and deteriorates.

Price: The price for the EPDM rubber (excluding labor costs) is about $75 to $450 per square (100 square feet).

Click Here To Read About the Pros & Cons of EPDM Roofing

Back to Top

Felt Underlayments

Underlayments are used to help protect your roof from any water and moisture that happens to get underneath the shingles. Underlayments are layered between the wood decking and the top layer of shingles.

They also protect your roof during the installation processes when your roof isn’t finished yet.

Materials Used:

Felt Underlayments can be made out of a variety of materials. Some materials are only used for specific styles or types of underlayments.

Some of the common materials used are:

- Polypropylene

- Polyester

- Cellulose

- Fiberglass

- Polymer-modified Bitumen

Style Options:

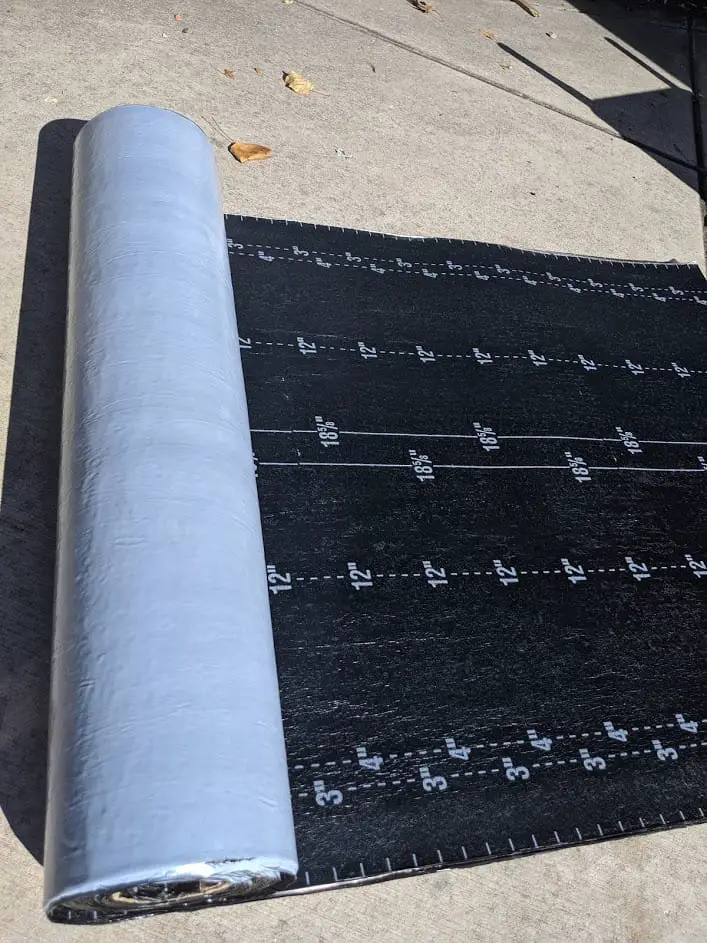

There are three types of underlayments that I will focus on. These are Tar Paper, Synthetic Underlayment, and Ice & Water Shield.

Tar Paper is typically cheapest out of all three. It is black and has a paper-like texture. Tar Paper comes in two different strengths, 15 lb (#15) or 30 lb (30#). There isn’t much of a price difference between the two strengths but there is a difference in quality. The #15 is generally less durable than the 30#. Typically the #15 can be used on steeper roofs while the #30 is better for less steep but not flat roofs.

The Synthetic Felt Underlayment generally has a plastic-like texture. Its color is typically a light gray color which aids in keeping your roof cooler. Synthetic Felt is much more durable than Tar Paper.

I am not a big fan of tar paper because of its durability level. I much rather use the Synthetic Felt Underlayment.

Synthetic Felt and Tar Paper have the same job, so you will only need one or the other when shingling a roof. However, depending on where you live you may also need another type of underlayment called Ice & Water Shield.

The purpose of Ice & Water Shield is to protect against Ice dams and water build-up that can occur during the colder seasons. As the weather fluctuates snow can melt into water, then freeze into ice. When this cycle happens, the water can actually travel back up underneath the shingles.

Ice & water shield protects the decking from this ice build-up. It is installed in high water flow areas like valleys, around pipe flashings, and on the bottom eaves of the roof.

The Ice & Water shield has a sticky backing that, when heated by the sun, it sticks down and seals itself to the wood decking.

Depending on local codes you may need to have more than one layer of Ice & Water shield going up the eaves to reach a certain height. It is best to check with your local codes if you suspect that you will need this underlayment.

Durability / Lifespan:

Durability: The durability of felt underlayments is most important when there is a delay between tearing off shingles and installing shingles. The felt protects the wood decking in the event of rain or snow.

Tar paper is not very durable, exposure to the suns UV rays break down the tar paper. Tar paper can only last a few days before it begins to crack and wrinkle, and eventually tear.

Synthetic felt is much more durable and strong. It is rated to protect the wood decking for up to 6 months even under direct sun exposure. So if you are doing a roof and you know it’s going to take longer than a few days to finish. You will definitely want to use the Synthetic Felt Underlayment.

Additionally, Synthetic Felt prevents fungal growth because it doesn’t absorb any moisture nor provide any food for the bacteria. Tar paper, on the other hand, absorbs some moisture making it more likely for fungi to grow.

Lifespan: As long as the underlayments were installed properly and in accordance with local codes, then the felt underlayments won’t need to be replaced until you need new shingles.

Price: The average price range for Tar Paper and Synthetic Underlayments ranges between $6 – $10 per square. Meanwhile, Ice & Water shield is about $34 – $91 per square.

Back to Top

FleeceBack

FleeceBack roof system is really just a style of other types of flat roof systems. FleeceBack roofs can be found with EPDM, PVC, and TPO. Because it is used in a lot of the other types of roof systems, I decided to talk about it more specifically.

Materials Used:

What is a FleeceBack roof? FleeceBack roof system is a Fleece material made out of polyester that can be added to the underside of EPDM, PVC, or TPO. It is adhered to the surface of the roof using 2-part fast adhesive foam.

The spray-on foam is made out of a 2-part polyurethane low rising adhesive foam.

The foam seals any cracks and seams in the roof decking which adds to insulation.

Style Options:

As previously mentioned FleeceBacking can be added to any of the other flat roof systems like EPDM, PVC, and TPO.

Due to this fact, it can come in a variety of colors like white, tan, gray, black, etc.

Typically, a FleecedBack roof system is faster to install than the typical flat roof system.

Because of the quicky and easy spray-on adhesive, FleeceBack roofs can be quickly applied over older roof systems like a smooth BUR roof.

Durability / Lifespan:

Durability: FleeceBack roofs are a bit more durable than their “regular” counterparts. In other words, a FleeceBack TPO is more durable than regular TPO.

The main difference is in how it is applied. The spray-on foam used to adhere the FleeceBack to the roof gives the material much more wind resistance. The uplift rating for FleeceBack roof can be rated as 1-465, 1-540, or 1-945.

Which is a lot stronger than if it was mechanically attached. For this purpose, FleeceBack roofs are a great option for high wind areas.

The FleeceBack roof also has a Class A fire rating and a Class 4 impact rating, meaning it can resist hail damage from up to 3-inch size hail.

Lifespan: Although more durable, FleeceBack Roofs are expected to last about the same as their counterparts which are about 20 – 30 years for TPO and PVC and 50+ years for EPDM Rubber.

Price: FleeceBack Roofs are much more expensive than their counterparts. FleeceBack roofs can cost about $93 – $133 per square for just the FleeceBack material itself, that’s not including the labor costs or the 2-part adhesive.

Click Here To Read About the Pros & Cons of FleeceBack Roofing

Back to Top

Metal Roof System

Metal roof systems are a great looking lightweight roof. It can be considered a green roof system because it can be made from recycled materials.

Materials Used:

Metal roofs can be made from a variety of materials. The common base metals that can be used are Steel, Copper, Aluminum, and Zinc.

The base metals are then covered in a metallic coating called a substrate. There are two main types of substrates which are Galvanized and Galvalume.

The Galvanized substrate consists of 100% Zinc coating. Zinc acts as a barrier that prevents corrosion and rust. Galvanized substrates are great for outdoor shade covers or roofs for animal structures. But they are not ideal for residential and commercial roof systems.

Galvanized substrates come with a rating system. Often you will see terms like G60, G90, G100. This is a rating for how much Zinc the substrate contains per 100 square feet. So a G60 rating means that there is 60% Zinc per 100 square feet. Usually the more Zinc the better protection the Galvanized substrate provides.

However, Galvalume, which is one of the best substrates is not 100% Zinc, it is actually a mix of two elements.

Galvalume typically is made of 45% Zinc and 55% Aluminum. Galvalume substrates are best for residential and commercial roof systems because they are much more durable than typical Galvanized substrates. I will explain more on that in the next section under durability.

After the metal has been covered in a metallic substrate, there is a paint coating that is applied which adds another layer of protection and additional styling.

There are three main types of paint coatings in which the quality varies from good, better, and best.

- KYNAR 500 also known as the PVDF is the best quality

- Siliconized Polyester (SMP) is better but not best.

- Polyester is a good coating but not better nor best.

KYNAR 500 is made out of polyvinylidene fluoride resin that is coated and baked on the metal. This one is the best and most recommend by manufacturers because it provides the most protection and is the most durable out of all 3 paint types.

Style Options:

Just as with all the other roof systems. Metal roofs come in a vast variety of styles. You can pretty much find any type of metal roof system to fit your needs.

They make metal roofs to mimic the shapes and styles of:

- Shingles

- Tile

- Slate

- Shake

- Clay

- Various Other Patterns

Stone-coated metal is another option that can be made to look like some of the various shapes listed above.

The various patterns have different shape names like corrugated, standing seam, PBU, 5V crimp, PBC, MasterLok, Rib, 138T, 238T, etc. You can check with your local roofing supply company to see what options are available near you.

It is also important to explain that you also have the option between exposed fasteners and concealed fasteners. The fasteners are the screws that hold the metal sheets to your roof.

Generally, the concealed fasteners are more durable and would be better for your home or commercial roof system. But if you are just making a simple shade canopy or driveway cover, then exposed fasteners would do the job just fine.

Price: The price will vary depending on the style, materials, and what coatings have been applied. The cost for a metal roof ranges from $75 to $1,500 per square. That cost range covers the metal on both sides of the spectrum. Starting with metal that should only be used for shade/animal structures to premium copper roofs. It is also excluding labor costs.

Durability / Lifespan:

Durability: Metal roofs are quite durable. They generally will have a Class A fire rating and a Class 4 impact rating for hail storms. Additionally, they can resist wind speeds at about 110 to 160 mph.

They are great for climates that experience heavy snow because they provide excellent protection against snow and ice build-up.

The points of weakness come when the coatings start to break down.

After a given period of time, the UV rays from the sun break down the coating resins and cause the color to fade and become chalky. The chalk that forms easily clings to skin and clothing when touched.

Siliconized Polyester and regular Polyester paint coatings don’t last nearly as long as the KYNAR 500 (PVDF).

The KYNAR 500 greatly outperforms the other paint coating systems by resisting the UV rays, pollutants, and other harmful weathering effects that cause color fade and chalking.

Furthermore, as the metallic substrates begin to break down, the metal will start to rust and corrode.

The Galvanized metals will rust much faster than the Galvalume coated metal roofs. This is why it is not recommended to use Galvanized metals on your home or commercial roof.

Another point of potential weakness is with exposed fasteners. As the season’s change and the metal expands and contracts over time the holes that once fit snug against the fastener begin to widen. This can lead to leaks.

For this reason, its important to choose the concealed fastener options for your residential or commercial roofing system.

If however, you are building a simple shade structure or animal structure, then the exposed fasteners are a viable option.

Lifespan: The life span of a metal roof system varies depending on the materials used and what coatings and substrates have been applied.

The most durable coating the KYNAR 500 (PVDF) is rated for about 20 years. The other coatings like the siliconized polyester (SMP) and polyester aren’t expected to last as long. As these types of coatings corrode, you can expect to see fading color and chalky residue.

If the metal is covered in the Galvanized substrate, then you can expect the roof to last about 20 to 35 years. On the other hand, if the metal was covered in the Galvalume then it is expected to last about 30 to 40+ years.

Click Here To Read About 21 Pros & Cons of Metal Roofs

Back to Top

Modified Bitumen

Modified Bitumen is a 2-part flat roof system. It was developed in Europe around the 1960s.

Materials Used:

Bitumen is another name for asphalt. Modified Bitumen is when polymers are added to asphalt to change the properties of it. There are two main types of polymers called SBS and APP. I will go into more detail about them in the next section below.

Modified Bitumen roofs contain two layers, a base layer, and a cap layer.

The base layer is made up of a reinforced sheet covered in the bitumen. The reinforced layer is made up of one of three option:

- Fiberglass

- Non-woven Polyester

- Composite, which is a combination of the two above.

The base layer provides waterproofing and a bonding surface for the cap sheet.

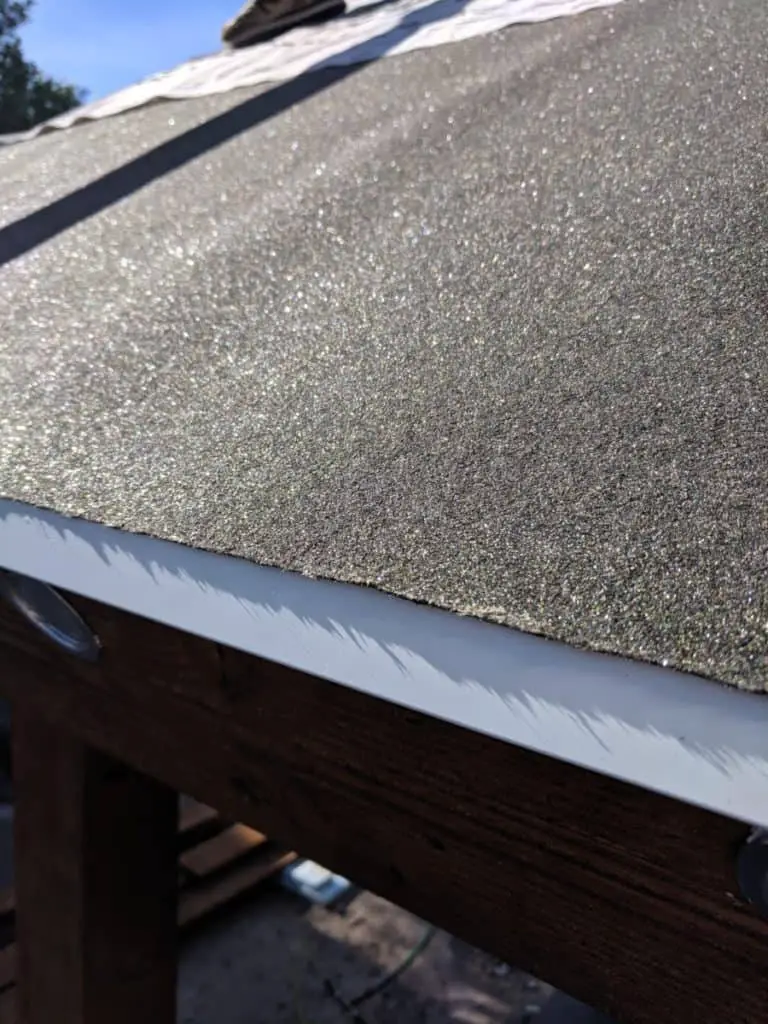

The cap sheet is made similar to the base sheet. But instead, the top layer is coated in granules that are made out of basalt, granite, or igneous rocks that have been ground down.

You can almost think of the cap sheet as one big shingle that can be rolled out.

There are several ways in which the cap and base can be installed on the roof which I have listed out.

- Self-adhesive: This means that each layer has a sticky backside that is covered in plastic. Upon removal fo the plastic the layers stick down and seal when the sun hits it.

- Heat adhesive/welded: This usually involves a propane torch to melt the bitumen and seal it together. SBS and APP act differently when heated.

- Cold adhesive: Bitumen that is liquid at room temperature is used. This reduces potential fire risk and toxic fumes that can come from the heat adhesive.

Style Options:

As mentioned before, there are two main types of modifiers SBS and APP. Here are some of the major differences between the two.

SBS

- Stands for: Styrene-Butadiene- Styrene

- It can be considered as the “Rubber Asphalt”.

- It’s more flexible and elastic than APP.

- Melts into a gooey paste.

VS APP

- Stands for: Atactic Polypropylene

- It can be considered as the “Plastic Asphalt”

- It’s more firm and brittle than SBS.

- Melts into a free-flowing liquid like hot wax.

Durability / Lifespan:

Durability: Both SBS and APP Modified Bitumen are durable roof systems. What really makes them stand out is their ability to withstand extreme cold weather without cracking or becoming brittle.

Modified Bitumen can stay flexible in temperatures as low as -22 degrees Fahrenheit or -30 degrees Celsius.

This system has a Class A fire rating, but compared to other roof systems it tends to lose its rating after 5-10 years. Especially if it has been walked on.

Resurfacing coats may be applied to the roof to restore the Class A fire rating.

Modified Bitumen roofs are not the best for high traffic areas. As it gets walked on, the granules covering the surface of the cap are removed, especially when it’s warm from the sun.

Additionally, it is not as resistant to impact damages from fallen objects or hail as other flat roof systems are.

Price: The cost for modified bitumen depends on what system is used to install it. A general price range would be about $150 – $250 per square.

Lifespan: The lifespan of Modified Bitumen is estimated to last about 10 – 20 years.

Click Here To Read About the Pros & Cons of Modified Bitumen

Back to Top

PVC Membrane

PVC roof system is a single-ply roof system much like EPDM rubber and TPO.

PVC is newer than EPDM rubber which has been around for almost 70 years. But older than TPO which was invented in the last 30 years.

PVC was invented in Germany around 1966 and is a good option for a flat roof system.

Materials Used:

PVC stands for Polyvinyl Chloride and is made up of ethylene and chlorine which are derived from processed petroleum or natural gas and salt respectively.

PVC membrane contains a polyester sheet which adds strength and durability.

It can be installed either mechanically with special screws and plates or fully adhered with a bonding adhesive like a FleeceBack roof system.

Similar to TPO, PVCs seams are heat welded together using a heat welder. If done properly this is more durable than EPDM which seams are sealed with an adhesive tape.

Style Options:

As with the other flat roof systems, there aren’t’ many options for style. But, one notable style is that PVC can be made to look like a standing seam metal roof by heat welding a rib on the roof.

Similar to TPO, PVC is offered in a variety of colors but the most common color is white because it reflects the sun’s UV rays and helps keep the building cooler.

PVC membranes also come in a variety of thicknesses ranging from 40 mils to 80 mils. Generally speaking, the thicker the membrane, the more durable and puncture-resistant it is.

Durability / Lifespan:

Durability: PVC is another great durable system. It is more puncture resistant than EPDM but slightly less durable than modern TPO.

PVC is resistant to hail damage and fire. PVC is a Class A fire rating and self-extinguishing once the heat source is removed.

The uplift wind rating for PVC varies depending on how it is installed. Mechanical installation is weaker than the pricer fully adhered FleeceBack system.

One big advantage of the PVC roof system is that it is very resistant to chemicals like oil and grease. It doesn’t absorb them nor get weakened by them. This makes it a preferred choice among restaurants that have a grease trap.

Price: The cost of PVC material is about $75 – $250 per square.

Lifespan: The expected lifespan of the PVC roof is about 20-30 years. However, one manufacturer boasts of 45+ years if it is well maintained on a regular basis.

Click Here to Read 19 Pros and Cons of PVC Roofing

Back to Top

Roof Garden

Roof Gardens are probably the most eco-friendly roof systems out there.

A roof garden is where plants and vegetation are grown on your roof.

Roof gardens significantly help to improve air quality, especially in urban areas.

They also make for a good roof system because it provides excellent insulation to the building. Keeping the building cooler in the summer and retaining the warmth in the winter.

Materials Used:

Roof Gardens are composed of several layers which means they will require a good support structure to hold all the weight.

A roof garden can weigh anywhere from 200 lbs to 1000+ lbs per square depending on the style of the garden.

The layers of the roof garden in order from bottom to top are:

- Roof Decking (All roofs will have some type of decking)

- Water Proof Layer (required)

- Root Barrier (required)

- Water Retention (required if no irrigation is set up)

- Filter Layer (required)

- Growing Media (required)

- Plants (required)

Water Proof Layer:

There are several types of waterproof layers that can be used. You can use single-ply roof systems materials like:

- EPDM

- PVC

- TPO

Or you can use waterproofing membranes that were designed for roof gardens specifically.

Whatever you decided to go with there are some important qualities that a good waterproof membrane must-have.

A) Thickness – you don’ t want the membrane to be too thick because there are many layers to the system and you don’ t want it to be too bulky.

However, you still want it to be durable. Most waterproofing membranes are about 80 mils to 90 mils. Anything more than that is probably too thick.

B) Installation Method – Any waterproofing layer for a roof garden must be a fully adhered system.

If you were to install EPDM, TPO, or PVC mechanically and it gets a hole in the membrane, water can leak into the wood decking and spread out across the entire roof underneath the membrane.

A fully adhered system means the whole membrane is “glued” down to the decking. This prevents water from spreading underneath the membrane if there was ever a leak.

The waterproof membranes that are made specifically for roof gardens are adhered by using either a hot adhesive like bitumen or a cold adhesive like a polyether.

Root Barrier:

The root barrier is designed to stop roots from growing any deeper. If roots get past this they can damage the waterproofing layer and cause a leak. The root barrier also acts as a second waterproofing layer.

Water Retention Layer:

The water retention layer holds water and moisture to nurture the plants. A common retention layer consists of plastic sheets with molded divets or cups that hold water.

This layer is not needed if you plan to have some sort of irrigation method set up. Otherwise, it’s a must-have because in order to keep the plants alive they need to have constant moisture.

Filter Layer:

The filter layer helps to keep the dirt or growing media from collecting in the cups of the water retention layer.

Growing Media:

There are many different options for growing media. Many of them are not typical soil, rather special engineered soil specific for this type of application.

Plants/Vegetation:

There are many different types of plants and the type you choose will vary on the style of roof garden you choose and how much maintenance you want to give it.

Some companies that specialize in roof gardens make pre-planted trays that you can just lay out on your roof garden system and water.

Style Options:

There are mainly two styles of roof gardens called Intensive and Extensive. You may also find some roof gardens that fall somewhere between the two.

Intensive:

Intensive roof gardens can contain almost any type of plant-like trees, shrubs, etc. These gardens are heavier than extensive because they require more soil for the deeper roots.

Intensive roof gardens are most commonly found on commercial roofs because they can support the heavyweight.

Extensive:

Extensive roof gardens are thinner and lighter than the intensive gardens. They require less soil because the roots of the plants don’t go as deep.

The plants used on extensive roofs are xerophytes, meaning they can grow in low water areas. It is also better to have plants that are fast-growing, easy to replace, and low maintenance.

Some examples of extensive plants are:

- Succulents

- Wild Flowers

- Grasses

- Herbs

- Sedum

Durability / Lifespan:

Durability: Green roofs are durable and help to reduce water run-off. If proper drainage is set up there won’t be much soil loss during a rainstorm.

High winds can cause some problems by blowing the growing media away. Some green roof companies offer a special mesh covering to prevent soil loss.

While you may have to replace plants or soil every now and then, the waterproofing layer should last for a while.

Price: The price is hard to give an accurate estimate for because there are so many factors that go into it. But an estimated range is anywhere from $100 a square to $400 a square. Although the more specialized you get, especially within the commercial intensive roofs the pricer it will get.

Lifespan: The lifespan varies with which types of materials are used in the system. A roof garden can significantly extend the lifespan of the single-ply roof membrane. In general, a roof garden can last anywhere from 30 to 50+ years.

Click Here to Read 21 Pros & Cons of Roof Gardens

Back to Top

Rubber Slate

Rubber slate performs better than some of the other synthetic slate options. Rubber slate can be a good alternative to real slate because it is more affordable and lighter.

Rubber slate weights about 275 lbs to 320 lbs per square which is a lot lighter when compared to the real slate which can weight about 800 lbs to 1500 lbs per square.

Materials Used:

Rubber slate is typically made out of recycled materials. Some manufactures recycle rubber tires and use an injection molding process to form the rubber slate panels.

Other manufacturers will also use other rubber materials like recycled EPDM and TPO.

The concentration of recycled materials varies between manufactures from 75% to 95% of recycled materials in each panel. One manufacturer estimated that they recycle about 250 to 1,000 tires to make one roof.

Style Options:

Most people don’t pay much attention to roofs unless they are in the market for a new roof. Even then, those people who do pay attention to roofs, few will be able to distinguish the difference between rubber slate and real slate.

Rubber slate roofs can be shaped into any style of slate. Some common textures are:

- Classic Flat Slate

- Rough Chiselled Edge Slate

- Wood Textured Shake

Rubber slate can come in a variety of colors like Black, a variety of Browns, Grey, Green, Purple, and Red.

Durability / Lifespan:

Durability: Rubber slate is very durable and known for its impact resistance. It has been rated up to the highest rating which is a Class 4 for hail impact resistance.

Due to the fact that some rubber slate is made out of recycled tires, it has a high UV resistant rating.

Tires contain a material called Carbon Black which is effectively resistant to UV radiation and color fade.

Rubber slate can also be rated for wind speeds up to 110 mph. But it only has a Class C fire rating.

Lifespan: While Rubber slate has a lifespan that is shorter than real slate it still has a long-lasting lifespan of about 50 years.

Price: The cost of materials for rubber slate is about $165 to $509 per square.

Click Here to read about 18 Pros & Cons |Synthetic Slate

Back to Top

Slate

Natural slate has been around since it was first popularized in the U.S. during the early 1600s. With all the advantages slate roof systems have to offer, its easy to see why slate has stuck around for so long.

Materials Used:

Many people today choose slate for its unique look and durability. Slate is made out of metaphoric rock that is processed from a natural quarry.

Due to the fact that slate is stone, it is 100% natural and completely eco-friendly. However, it is also a heavy roof system.

Natural Slate roofs can weigh anywhere from 800 to 1500 lbs per square. This means if you have a roof that is 17 squares that equates to a minimum of 13,600 lbs of stone!

With that said, if you are going to go with this option, you must have the structure of your roof inspected to ensure that it can support the weight of all that heavy stone.

Style Options:

It is difficult to have a lot of style options when a roof such as slate is natural. But you can get slate from different parts of the world which would have some variations depending on the minerals it contains.

“Old Swan House” by HerryLawford is licensed under CC BY 2.0

“Old Swan House” by HerryLawford is licensed under CC BY 2.0

Some of the common natural slate colors you can find are a variety of Blacks and Grays. You can also find Green, Red and a Gray-ish purple.

The other option you have is to change the shape of the slate tiles. The most common slate tile is the basic rectangular shape, but other cuts can be found like rounded, smooth, rough, abstract squares, etc.

Durability / Lifespan:

Durability: Slate roofs are known for their high level of durability. Because its made out of stone, its naturally durable to UV rays, fluctuating temperatures, and fire.

Slate has a high fire-resistant rating of Class A. It also has a high impact rating based on the thickness of the slate tiles.

A 3/8″ thick slate tile has a Class 4 impact resistance, meaning it did not break or crack with 2-inch sized hail. A 1/4″ chick tile has a Class 3 rating which is less than the Class 4 rating.

You can view the test performance results for fire and hail impact tests by visiting these links.

National Slate Association Impact Test Report

National Slate Association Fire Test Report

National Slate Association Website

Those impact damage ratings don’t mean that slate is indestructible. Slate is actually kind of fragile. The quality of slate that allows roofers to cut and shape the slate also makes it fragile to walk on.

Lifespan: The average expected lifespan for a natural slate roof is 75 to 150+ years.

Price: Depending on the thickness, color, and shape of the natural slate tiles. Slate can cost anywhere from $500 to $1200 just for the materials. This is more expensive than most other roof systems but I believe if you can afford it, it’s well worth the money.

Click Here To Read About 18 Pros & Cons of Slate Roofs

Back to Top

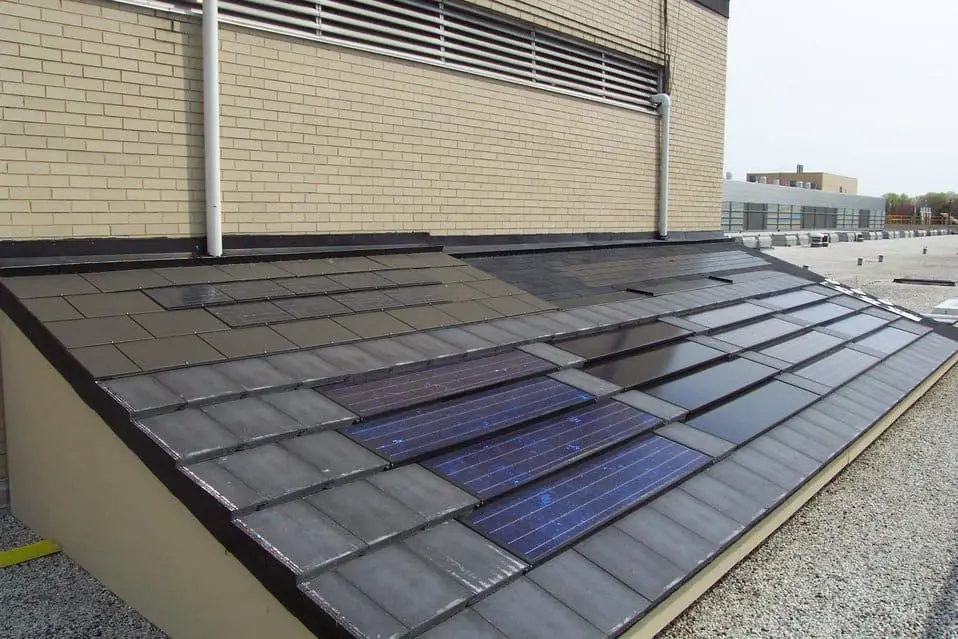

Solar Tiles

Solar Tile roofs are the future of energy-saving roof systems. As you may already know, solar roof tiles are still being developed and refined. One day we could live in a world where every home has a solar roof.

Materials Used:

Solar tiles are made out of the same basic materials as any other solar product. The solar roof tiles contain Photovoltaic materials like monocrystalline or polycrystalline cells.

They are linked together forming a circuit that takes DC power generated from the panels and turns it into AC current for your home. This can save you money and help to reduce your carbon footprint.

To learn more about how solar tiles are made you can check out this patent design here.

Style Options:

There are two main types of solar roof styles the shingle and the tile. This is excluding the classic solar roof panels. Solar shingles link together to appear like shingles but they rest on top of an existing roof system much like the classic solar panels.

Solar tiles are unique because they exist as part of the roof system. This means there is no other roofing system needed below the solar tiles. The solar tiles act as the roof system and the solar system.

When comparing the two systems the shingles produce about 110 Watts per meter squared (110 Wp) while the tiles produce about 70 watts per meter squared (70Wp).

Durability / Lifespan:

Durability: Solar roof tiles are pretty durable. They have a Class A fire rating and a Class 4 Hail Damage impact rating. It is also rated for wind speeds up to 130 mph.

Lifespan: Solar Tiles are stronger than the typical solar panels. Solar panels are expected to last about 25 years. So Solar Tiles are estimated to last longer probably about 20 – 40 years. But really, only time will tell how long it will last. Tesla’s Solar Roof Home was only recently unveiled in October 2016.

Price: The price for solar roof tiles depends on what the company that produces it. Here are three major companies price ranges:

- Tesla: $2,125 -$2,600 per square

- SunTegra: $ 1,680 – $1,775 per square

- PowerHouse: $ 1,100 – $1,185 per square

Click Here to Read 21 Pros & Cons of Solar Tiles

Back to Top

Spray-On Roof

Spray-On Roof system or SPF has been around since 1964. This roof system is mostly used in the commercial side of roofing for flat roofs. The convenience of simply spraying on a roof and the durability in high wind areas make this a great flat roof option.

Materials Used:

Spray on roofs are installed by spraying 3 different layers which are:

- Base Foam Coating

- Top Coating

- Granule Coating

The foam is made out of polyurethane while the top coating is made out of silicon.

The foam coating adds a good layer of insulation to the building. While the silicon coating protects the foam from weathering.

One downside to the SPF roof is that it cannot be applied during the cold seasons. Temperatures during installation must be about 55 degrees and Sunny. If its rainy or cold weather then it will prevent the foam from curing properly.

Style Options:

There aren’t many style options for the SPF roof system. You may come across some varying colors but most commonly you will see white or gray.

The main difference between different SPF roof systems is the thickness levels. The base foam coating ranges between 1.5 inches to 13 inches thick while the silicon coating ranges from 10 mils to 12 mils.

The varying thickness will directly affect the durability and lifespan of the roof system.

Durability / Lifespan:

Durability: SPF roof system has a strong resistance to wind. Their wind uplift rating is 160 lbs per square inch, making this system perfect for high wind areas.

One downside to the SPF roof system is that its not as strong against impact resistance. The SPF coatings can withstand 40 lbs per square inch which means you can walk on it without damaging it but it may not hold up as strong against a hail storm or bird-pecking.

To prevent this they have started to add the granule coatings which help against bird pecking.

Lifespan: SPF roof system can last a lifetime if properly maintained. The silicon coating provides water resistance and protects the Foam layer from UV rays. The silicon coating can last anywhere from 10 to 20 years depending on how thick it is.

A 20 mil coating will last 10 years, a 25 mil coating will last about 15 years and a 30 mil coating will last about 20 years. Once the silicone coating wears down to about 8 mils then its time to reapply a new layer of silicon.

If properly maintained, an SPF roof can last 50+ years as long as the silicon layer is continually maintained. Manufacturers recommend a professional inspect your SPF roof every 2 years or after any possible damaging event like a hail storm. If any damages are found, a simple recoating of the silicon spray is usually all that is necessary.

Price: The cost to reapply the silicon layer is about $2 – $4 per square or 1/2 to 1/3 of the original installation costs. To spray on all 3 layers of the SPF roof system will cost about $400 – $700 per square.

Click Here for 17 Pros & Cons of SPF Roof System

Back to Top

TPO

TPO stands for Thermoplastic Polyolefin. This is a single-ply flat roof system that the newest of all the flat roof systems.

TPO was invented around the year 1986 in Michigan by Montell, a company which now goes by Basell, making TPO only about 30 years old.

TPO was invented to be a durable flexible roof. TPO is becoming more popular than EPDM and PVC because of its low cost and durability.

Materials Used:

TPO is made up of Thermoplastic Polyolefin layers. Each layer is made from Ethylene propylene rubber, and talc carbon filler or fiberglass.

The fillers add to the strength of TPO, making it a strong roof option.

TPO can be installed in one of three ways.

- Mechanically Attached – secured using special screws and plates.

- Ballasted – (See Built-Up Roof Style Options)

- Fully Adhered – It can be adhered to the roof by tar mopping or by a fleecedBacked system with a 2-part foam.

One key difference between EPDM and TPO is that TPO has welded seams. EPDM’s seams are sealed using special tape or liquid adhesive. While TPO’s seams are melted together using a heat welder.

Style Options:

There are really only two main things that can change with TPO to give variety and style.

The first is color, TPO can come in a variety of colors like Gray, Tan, and most commonly used white. Buyers can also order special customized colors from manufactures.

Additionally, TPO comes in a variety of thicknesses ranging from 40 mils to 80 mils. Generally, the thicker the material the more durable it is.

Durability / Lifespan:

Durability: TPO is known to be more durable than EPDM rubber and slightly more durable than PVC. It has a strong resistance to tears and punctures.

However, because TPO is still fairly new you must take caution when choosing a brand of TPO. Not all brands are created equally. Make sure the manufacturer is a reputable company or else it may not be as durable as you expect.

Some brands that I would trust are larger manufacturer companies like GAF and Carlisle, etc.

TPO is resistant to fungi and UV radiation from the sun. The white TPO is especially beneficial because it reflects the sun helping to keep the building cooler in the summer.

TPO can have a Class A fire rating and a Class 4 impact rating. The wind uplift rating varies depending on how the TPO is attached. A fully adhered roof will have a strong uplift rating than a mechanically attached roof.

Price: The cost of materials for TPO can range between $150 to $500 per square.

Lifespan: The expected lifespan of TPO is 20-30 years. Although this type of roof system is only about 33 years old. I would bet we can expect to see some improvements as the technology develops.

Click Here for 18 Pros & Cons of TPO

Back to Top

Wood Shingle/Shakes

Wood can be a great roof option for those who are looking for a unique style or a lightweight roof material. Another great thing about wood roofs is that they are biodegradable.

Materials Used:

There are several types of wood that are used to make shakes. Some of the common types of wood are:

- Western Red Cedar

- Atlantic White Cedar

- Pine

- Spruces

- Cypress

- Redwood

The wood is cut into various sizes for roofs and siding. The size of each piece can range anywhere from 16 inches to 24 inches long and 1/4 inch to 1 inch thick.

The wood then undergoes various treatments like kiln and pressure treatments. The kiln treatment helps to remove moisture from the wood pieces. The pressure treatment can consist of some elements like copper, chromium, and arsenic.

Style Options:

There are two main types of wood roof styles, wood shingles, and wood shakes.

Wood Shake VS

- Hand Split – Each shake has its own unique texturing. Which gives the roof more of a rustic look or a historic look.

- Pieces don’t always lay flat nicely. If not installed properly this can reduce wind resistance.

- Costs about $175 – $300 per square.

Wood Shingle

- Machine Cut & Tapered – This gives the wood clean-cut edges.

- Pieces lay flat and easily fit together. This gives it more of a uniform flat look.

- Different Shapes- Wood Shingles can be cut into different shapes besides the typical rectangular look.

- Costs about $200 – $300 per square.

Durability / Lifespan:

Durability: Wood roofs are pretty durable but just as with other roof systems, they have their weaknesses.

One of the biggest concerns is fire resistance. Because it’s made of wood, it is naturally prone to catch on fire during certain events.

Due to this reason wood roofs are banned in certain fire-prone areas. Some homeowner’s insurance companies may increase rates for wood roofs or may not cover them at all.

If this roof system is something you are considering check with your local city regulations to see if there are any requirements or restrictions for wood roofs.

Manufacturers have developed certain ways to help wood roofs become more fire-resistant.

The first way is a spray-on fire retardant. This is effective but only for a couple of years. Over time as the UV rays shine on the roof, this coating breaks down. This means about every 2 years you will have to have a new coating applied to maintain the level of fire resistance.

The second method is a type of pressure treatment that is more durable than the spray-on retardant.

When the wood is put through a special pressure treatment the chemicals that aid in fire resistance adhere to the surface of the wood permanently. This allows for much greater lasting fire resistance. Further processes can be done to ensure all levels of fire resistance Class A, Class B, and Class C fire ratings.

Click Here to Learn More About Pressurized Fire Treatment

There is also a pressure treatment that is used as a preservative which helps to prevent fungal growth and decay.

Wood shingles are usually rated for wind speeds up to 173 mph while wood shakes are rated for wind speeds up to 245 mph.

Wood roof systems can have a Class 3 or Class 4 impact rating. Where the highest, Class 4 resists 2-inch sized hail.

Generally, the thicker the wood the more durable it will be against the elements.

Lifespan: Depending on the style, type of wood, and what processes the wood has gone through to build up durability will determine how long it lasts. But generally speaking, you can expect your wood roof to last about 20 to 25 years.

As the wood weathers and breaks down, you will see a change in color from the natural brown to more of a silver-gray color.