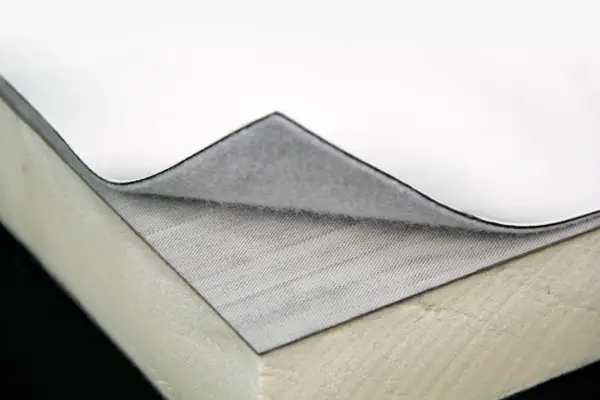

What is FleeceBack Roofing?

FleeceBack roof system is a reinforced material made out of polyester that can be added to the underside of low slope roof membranes like EPDM, PVC or TPO. It is used to give the material extra strength.

FleeceBack roofing membranes are adhered to the surface of the roof using 2-part polyurethane low rising fast adhesive foam.

Due to the fact that FleeceBack roofs are used with a variety of different membranes, there is also a wide variety of color options that are available. The most common color is white but tan, gray, and black are also viable options.

Pros:

1.Fast Installation:

FleeceBack roofs are easy and fast to install. They require fewer workers and less time to get the job done. This reduces the labor costs associated with installing this type of roof.

2. Adhered with Spray Foam:

The 2-part spray foam aids in the fast installation process. But it also adds insulation to the roof and helps seal any cracks that may be on the roof.

3. Wind Resistance:

The spray foam adhesive gives the FleeceBack roof strong wind resistance. It is stronger than any mechanically attached system. The wind uplift rating for FleeceBack roof can be rated up to 1-465, 1-540, or 1-945.

4. Increased Impact Resistance:

The added FleeceBack gives the roofing membranes more strength to resistance against punctures and impact damages. This gives the roof a Class 4 hail damage rating and helps it to resist impacts from falling branches or clam dropping.

5. Low VOC:

FleeceBack roofs have low VOC or Volatile organic compounds meaning that the chemicals used to install this roof will not evaporate quickly and cause the workers installing the roof to inhale toxic chemicals. Other roof systems like heat-applied modified bitumen have a higher VOC. You can read more about modified bitumen in this article.

6. Energy Efficient:

FleeceBack roofs are resistant to UV radiation. The material, especially the white color, reflects the sun’s rays. This, with the added insulation from the foam, helps to keep the building cool and reduce energy costs.

7. Versatile:

FleeceBack roofs can be used on any low slope roof system. It can be used on both commercial or residential roofs. However, due to its high wind resistance, it is primarily used for commercial buildings. In most cases, its a bit over the top to use FleeceBack on residential homes because regular roof membranes like TPO or PVC will do the job just fine.

8. Life Expectancy:

The life expectancy for FleecBack roof can range anywhere from about 20 to 30 years. Which is about the same as the other low slope roof system options.

9. Price:

The price for a FleeceBack roof is about $93 – $133 per square (100 square feet in 1 square) just for the materials. This price excludes labor costs which are also expected to be less than its counterparts. I made a table comparing the different prices of 17 roof materials which you can read here.

10. Sealed Roof:

This is another big benefit, a FleeceBack roof is a sealed roof. The seems do not need to be heat-welded or sealed with an adhesive tape like regular TPO or EPDM need. It is simply sealed with the polyurethane foam.

You can check out this video which shows how this roof system is installed.

11. Quiet Installation:

FleeceBack roofs are quieter to install than mechanically attached roof systems. Instead of banging and drilling noises that echo throughout the building. FleeceBack roof just has the sound of the outside pump that is used to spray the foam.

12. Easy Cover-Up:

Another advantage of a FleeceBack roof is that it is easy to cover up an existing roof system. The foam adhesive readily attached the FleeceBacked membrane to any previous membranes below or to the roof floor.

Cons:

1.Temperature:

The 2-part polyurethane foam must be installed in temperatures above 40 degrees Fahrenheit. Any colder then the foam will not set up nor cure properly. This is different from PVC or TPO which can be installed during cold temperatures using heat welding.

2. Overspray:

Overspray can be a problem with FleeceBack Roof but not as severe as a Spray-On Roof. You can read my article about Spray-On Roofs here. Overspray is when the 2-part foam is sprayed onto unintended objects. To prevent this a roofer must use a piece of cardboard or some other type of screen to catch any excess spray foam. This is especially important around the edges of the building. You don’t want to spray foam on someone walking on the sidewalk down below.

3. Repairs:

This may not be a disadvantage to everyone but Fleeceback roofs are more technical to repair. I would not recommend anyone repair their own Fleeceback roof unless they have the technical knowledge and experience to do so. It is always best to hire a professional roofer to fix any repairs that may be needed.

4. Must Be Dry:

Another potential downside to Fleeceback roof is that it must be dry in order to fully install it. If the roof is wet, then the spray foam adhesive will not set properly and seal the FleeceBack membrane to the roof.

5. Clean:

Another time-consuming issue is that Fleeceback roofs must be really clean for the roof to adhere fully. If there is a lot of dust or debris then the foam will not make a good contact with the roof surface and won’t make a good seal. This can make it more challenging if you have to tear off a previous layer before you can install FleeceBack because you will have to ensure that the surface is free of dirt and debris.

6. One Layer Cover-Up:

Technically, you are only allowed to cover one layer with Fleeceback roof. This can be a problem because many low slope / flat roof systems have multiple layers which would mean you would have to remove some layers then make sure it’s clean.

Alternative Options:

If a FleeceBacked Roof doesn’t sound like the right kind of roof for you. There are at least 6 other options available for low slope/flat roofs that I have placed in a nice little chart below with links to other Pros & Cons lists for that material.

If you are interested in other roofing options I recommend you take a look at this article which I spent several months writing. It is a complete guide where I explain about 17 different types of roofing materials that are used today. You can read the article here.

This chart table shows the 6 other options for low slope roofs.

| Type | Description |

|---|---|

| Built-Up Roof | Built-Up Roof (BUR) is made up of multiple layers alternating between fabric material and bitumen (asphalt). Finally, the last layer is topped with rocks or gravel. Click Here to Learn More about Built-Up Roof. |

| EPDM | EPDM stands for Ethylene Propylene Diene Terpolymer. It’s a rubber-based material. Click Here to Learn More about EPDM. |

| TPO | TPO stands for Thermoplastic Polyolefin. This is a single-ply flat roof system that the newest of all the flat roof systems. Click Here to Learn More about TPO. |

| Spray-On Roof (SPF) | Spray-On roof has been around since 1964 and involves spraying layers of polyurethane and silicone. Click Here to Learn More about Spray-On Roof. |

| PVC | PVC stands for Polyvinyl Chloride and is made up of ethylene and chlorine which are derived from processed petroleum or natural gas and salt respectively. Click Here to Learn More about PVC. |

| Modified Bitumen | Modified Bitumen is a 2-part flat roof system. It was developed in Europe around the 1960s. It comes in two different types. Click Here to Learn More about Modified Bitumen. |

Related Questions:

Is FleeceBack roof good? FleeceBack roof is known for its high wind resistance and strong uplift ratings. It is also energy efficient helping you to save costs on heating and cooling. These qualities make it a good roof for commercial and residential buildings.

Can you put shingles over FleeceBack roof? You can’t put shingles on FleeceBack roof if the slope is lower than a 2/12 this is the minimum slope need for shingles to work effectively.