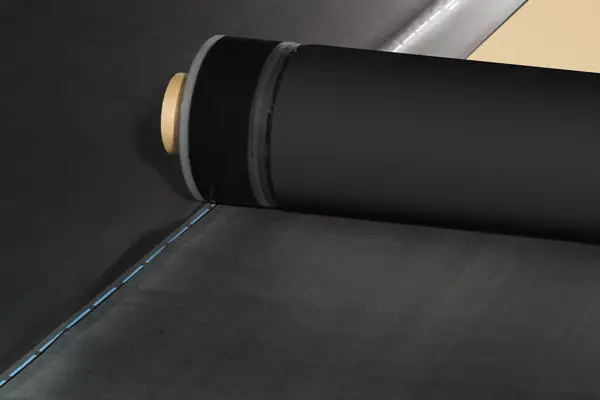

What is EPDM Rubber Roof?

EPDM stands for Ethylene Propylene Diene Terpolymer. The Terpolymer is composed of three different Monomers, hence the “M” in EPDM.

EPDM rubber is the same type of black rubber material that is used to seal your car doors, windows, and trunk.

EPDM is a rubber-based material that is part of a single-ply roof system. EPDM can be secured in one of three ways:

- Fully Adhered – using a special liquid adhesive or tape.

- Mechanically attached – using a designated type of screw and plate.

- Ballasted – secured by the weight of stones. Click here for more about Ballasted roofs.

Worried About Doing the Work Yourself?

I recommend finding a professional roofing contractor through our trusted partner Home Advisor because they allow you to get up to 4 quotes for free. This allows you to compare and choose the best roofing professional for your needs. Check them out by clicking this link.

Pros:

1.Light Weight:

Epdm Rubber is a lightweight roof system. It weighs less than 2 lbs per square or 100 square feet.

2.Easy to Install:

EPDM Rubber is easy to install because it doesn’t require any heat welding or specialized tools. It also comes in rolls just like TPO and PVC making it easy to roll out across the surface of the roof.

3.Life Expectancy:

EPDM rubber roof system is expected to last anywhere from 20 to 30 years which is about the same lifespan as asphalt shingles.

4.Flexibility:

EPDM is more elastic than some of the other roofing low slope roofing materials like TPO, PVC, etc.

5.Price:

EPDM rubber costs about $75 to $450 per square (100 square feet) for materials. This is cheaper than most other flat roof systems.

6.Fire-Resistance:

EPDM rubber is quite resistant to fire. They even make some EPDM with fire retardant compounds that help put out the flame. You can learn more about the fire retardant compound here.

7.Temperature Fluctuations:

Due to its elasticity properties, EPDM rubber has a wide range of temperatures it can tolerate. It can withstand temperatures as low as -60°F or has high as 300°F.

8.Wind Uplift:

EPDM Rubber has a strong wind uplift rating which can range anywhere from 1-60, 1-90, and 1-120. This is great for commercial roofs where this is important.

9.Impact Resistant:

EPDM has good resistance to impact damages especially if it is reinforced like the FleeceBack roof system. However, as the EPDM rubber nears the end of its lifespan, it becomes more fragile and vulnerable to impact damages.

10.Easy to Repair:

EPDM is easy to repair and maintain. So easy that a non-professional could fix a hole without much difficulty.

11.Inexpensive to Repair:

EPDM rubber is less expensive to repair than other flat roof systems. It requires less work and equipment which reduces the costs.

Cons:

1.Absorbs UV Rays:

This can be an advantage or a disadvantage depending on the type of EPDM material used. Most EPDM rubber is black which means it absorbs UV rays and heats the roof. They do make white EPDM rubber that reflects UV rays and saves on energy costs. But most EPDM rubber used is the regular black color.

2.Seams:

From what I have seen, the seams for EPDM do not hold up as well as the seams for TPO, or PVC. The adhesive between the seams can break as the EPDM rubber expands and contracts with the changes in temperature.

3.Curb Appeal:

EPDM rubber is not an “eye candy” by any means. It’s black and looks like an inner tube that doesn’t look as good as the TPO or PVC which is a clean elegant white look.

4.Must be Installed Properly:

If the EPDM rubber roof is not installed properly it will leak from day one. It’s important to higher a roofing company that knows what they are doing.

5.Corrodes with Petroleum-Based Products:

EPDM rubber will break down when exposed to petroleum-based products. You can check out this link to see how certain chemicals affect EPDM rubber.

Alternative Options:

If an EPDM Roof system doesn’t sound like the right kind of roof for you. There are at least 6 other options available for low slope/flat roofs. Below I have placed a nice little chart with links to other Pros & Cons lists for the other 6 low slope roofing options.

If you are interested in other roofing options I recommend you take a look at this article which I spent several months writing. It is a complete guide where I explain about 17 different types of roofing materials that are used today. You can read the article here.

This chart table shows the 6 other options for low slope roofs.

| Type | Description |

|---|---|

| FleeceBack roof | FleeceBack roof system is a Fleece material made out of polyester that can be added to the underside of EPDM, PVC, or TPO. It is adhered to the surface of the roof using 2-part fast adhesive foam. Click Here to Learn More about the FleeceBack roof system. |

| Built-Up Roof | Built-Up Roof (BUR) is made up of multiple layers alternating between fabric material and bitumen (asphalt). Finally, the last layer is topped with rocks or gravel. Click Here to Learn More about Built-Up Roof. |

| TPO | TPO stands for Thermoplastic Polyolefin. This is a single-ply flat roof system that the newest of all the flat roof systems. Click Here to Learn More about TPO. |

| Spray-On Roof (SPF) | Spray-On roof has been around since 1964 and involves spraying layers of polyurethane and silicone. Click Here to Learn More about Spray-On Roof. |

| PVC | PVC stands for Polyvinyl Chloride and is made up of ethylene and chlorine which are derived from processed petroleum or natural gas and salt respectively. Click Here to Learn More about PVC. |

| Modified Bitumen | Modified Bitumen is a 2-part flat roof system. It was developed in Europe around the 1960s. It comes in two different types. Click Here to Learn More about Modified Bitumen. |

Related Questions:

Is EPDM waterproof? EPDM is waterproof. It is a rubber based material that is used in a variety of applications ranging anywhere from roof systems to cars.

Can you put shingles over EPDM rubber roof? Generally, no. You can’t put shingles over EPDM because EPDM rubber is used on a low slope roof. Asphalt shingles require a minimum slope of 2/12, meaning every 12 inches the slope rises 2 inches. If the slope of the EPDM roof is less than 2/12 then you can’t put shingles on it.

Click this link to learn how to find the slope of your own roof.