What is TPO?

If you are thinking about TPO as your next roof system, I would seriously consider TPO as an option. TPO is the newest innovation for low slope roofs. It was invented in the year of 1986, which makes it only about 34 years old.

TPO is a single-ply low slope roof system. TPO stands for Thermoplastic Polyolefin which is made up of blends of Ethylene polypropylene rubber, and talc carbon filler or fiberglass.

TPO can be installed in one of three ways.

- Mechanically Attached – secured using special screws and plates.

- Ballasted – (See Built-Up Roof Style Options)

- Fully Adhered – It can be adhered to the roof by tar mopping or by a fleeced-backed system with a 2-part foam.

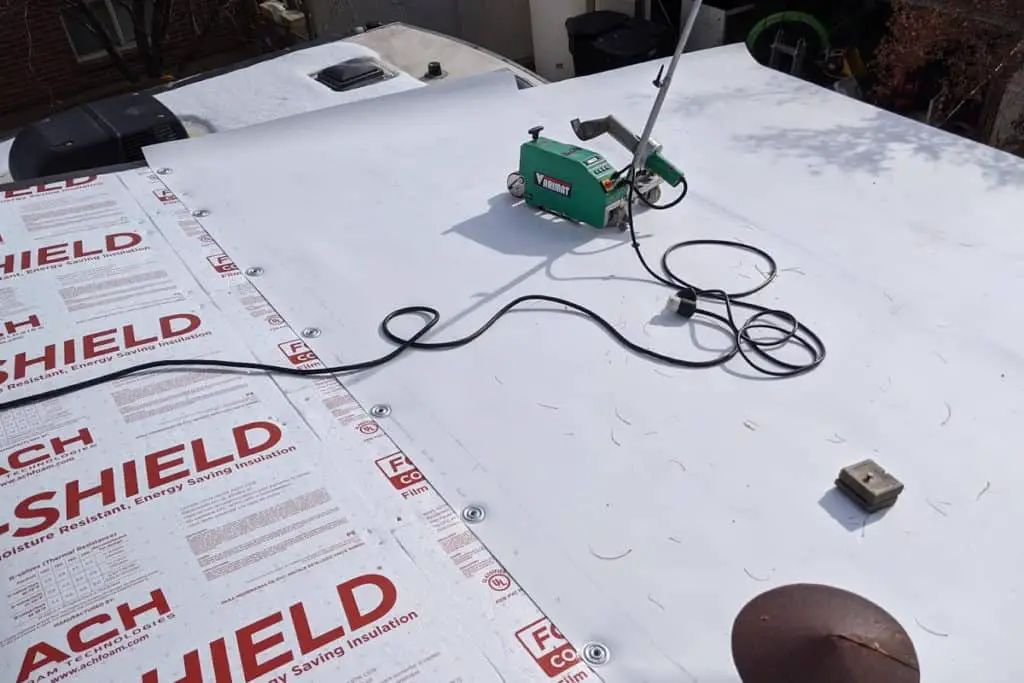

The seams on TPO are heat welded unlike the seams on an EPDM roof which use an adhesive. You can see a picture of a heat welder on Amazon here.

TPO comes in a variety of thicknesses ranging from 40 mils to 80 mils. Generally, the thicker the material the more durable it is.

There is no perfect roof material, everything has its strengths and weaknesses. Here are both the advantages and disadvantages of TPO roofing that you should consider.

Pros:

1.Durable:

TPO is generally more durable than other low slope roof systems. It has a strong resistance to tears and punctures.

2.Fungi Resistant:

TPO is inherently effective in preventing fungi growth because of its great water-resistance.

3.Variety of Color Options:

TPO can come in a variety of colors like Tan, Gray, and the most commonly used white. Some manufacturers may also make customized colors.

4. UV Resistant:

TPO is very resistant to UV rays. It also comes with the benefits of the white color option. With that said, all the membrane color options reflect UV radiation really well helps you save cooling costs. You can learn more about TPO’s UV resistance here.

5. Impact Resistance:

TPO has a Class 4 impact rating. Which means during the tests it withstood a 2″ size piece of simulated hail. This doesn’t mean the TPO is impervious to impact damages but that it will hold its ground during the storm.

6.Life Expectancy:

The life expectancy of TPO is about 20-30 years. Which is about the same as the other low slope roof options. Considering that TPO is still a fairly new product and that the materials used are being improved and changed we can probably expect to an increased lifespan in the future.

7.Low Maintenance:

TPO doesn’t require much maintenance. Maybe an occasional inspection or even a repair if needed.

8.Low Environment Impact:

TPO is better for the environment than EPDM. It exceeds the Energy Star requirements. You can learn more about TPO’s impact on the environment and UV resistance by checking out the Cool Roof Rating Council.

9.Easy Installation:

Although technical, TPO installation is easy and quick. TPO comes in large rolls that can be easily spread out across the roof. This reduces the number of seams and makes for a quicker installation.

10.Light Weight:

TPO is a lightweight roof system. TPO, at most, weighs about 0.40 lbs per square foot or 40 lbs per square. This is much lighter than asphalt shingles which weigh about 150 to 240 lbs per square.

11.Flexible:

When heated, TPO is flexible and malleable allowing it to easily wrap around and form on pipes and flashing. It is also flexible with temperature and season changes.

12.Versatility:

TPO can be used on both residential and commercial roofing systems. It can not only be used on flat roofs but low sloped roofs as well.

13.Temperature:

Another great advantage of TPO is that it can be installed during winter seasons. TPO is first attached to the roof, then sealed down with the heat welders. As long as the heat welders are able to bring TPO up to temperature, between 800˚F (427˚C) and 1,100˚F (593˚C), then TPO will seal down with no problem.

Cons:

1.Different Brands:

As with many products, not all brands of TPO are created equally. Especially because TPO has only been around for about 30 years or so there is still some room for more development. Products from inadequate brands won’t last nearly as long as a quality brand. So make sure to do your research to ensure that when you buy, you are buying a quality product. Or make sure you are hiring a contractor with TPO experience.

2.Price:

TPO is more expensive than most of the other low slope roof systems. But that is to be expected because it is also one of the newest low slope materials. The price for the TPO is about $150 – $500 per square (100 square feet = 1 square).

3.Fire Resistance:

TPO can have a class A fire rating but the material itself doesn’t contain self-extinguishing characteristics like PVC. TPO can become more fire-resistant if it is used in a Ballasted roof system or if a fire-retardant layer is placed underneath the TPO. Below is a video showing the differences between TPO and PVC as they burn.

4.Technical Repairs:

A TPO repair requires special tools like a heat welder which can get costly and technical for the average person. It is always recommended to hire a professional to make any repairs on your roof if they are needed.

5.Slippery:

TPO can get very slippery when its wet, frosted, snowy or icy. This technically can be both an advantage and a disadvantage. It is a disadvantage when you need to walk on the roof in those limited conditions. It’s an advantage when it comes to its water-repelling abilities.

6.Novelty:

TPO is still being developed and had only been around for about 34 years. Only time will tell what new things we will learn about this innovative roof system.

Alternative Options:

If an TPO Roof system doesn’t sound like the right kind of roof for you. There are at least 6 other options available for low slope/flat roofs. Below I have placed a nice little chart with links to other Pros & Cons lists for the other 6 low slope roofing options.

If you are interested in other roofing options I recommend you take a look at this article which I spent several months writing. It is a complete guide where I explain about 17 different types of roofing materials that are used today. You can read the article here.

This chart table shows the 6 other options for low slope roofs.

| Type | Description |

|---|---|

| FleeceBack roof | FleeceBack roof system is a Fleece material made out of polyester that can be added to the underside of EPDM, PVC, or TPO. It is adhered to the surface of the roof using 2-part fast adhesive foam. Click Here to Learn More about the FleeceBack roof system. |

| Built-Up Roof | Built-Up Roof (BUR) is made up of multiple layers alternating between fabric material and bitumen (asphalt). Finally, the last layer is topped with rocks or gravel. Click Here to Learn More about Built-Up Roof. |

| EPDM | EPDM stands for Ethylene Propylene Diene Terpolymer. It’s a rubber-based material. Click Here to Learn More about EPDM. |

| Spray-On Roof (SPF) | Spray-On roof has been around since 1964 and involves spraying layers of polyurethane and silicone. Click Here to Learn More about Spray-On Roof. |

| PVC | PVC stands for Polyvinyl Chloride and is made up of ethylene and chlorine which are derived from processed petroleum or natural gas and salt respectively. Click Here to Learn More about PVC. |

| Modified Bitumen | Modified Bitumen is a 2-part flat roof system. It was developed in Europe around the 1960s. It comes in two different types. Click Here to Learn More about Modified Bitumen. |

Related Questions:

Is a TPO roof good? TPO is one of the latest roof innovations for low slope roof systems. It combines the advantages of both PVC and EPDM. However, it does come with its own disadvantages. A better question would be is TPO good for your specific needs?

Does TPO shrink? From what we know about TPO, it does not shrink. However, the seams on TPO may fail if it was not installed properly by a professional roofer. This would lead to a leaky roof and water damage.